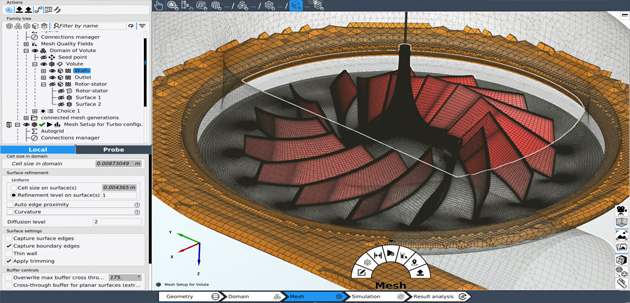

On-Demand Webinar: Toyota Reduces Simulation Time with Automatic CFD Pre-Processing

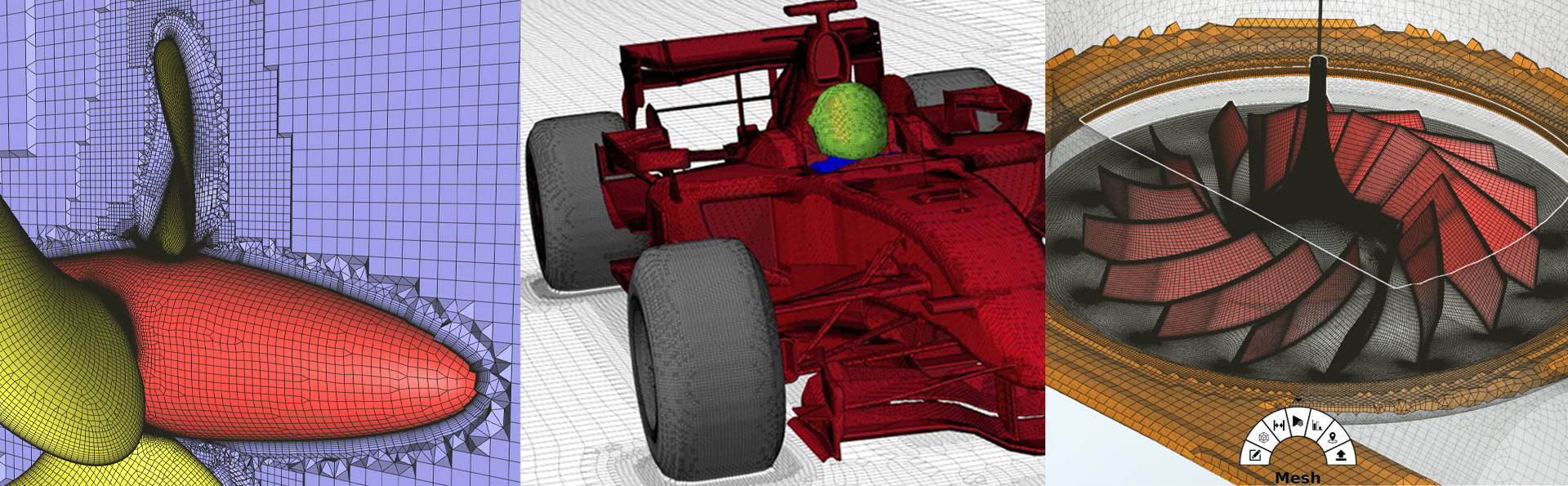

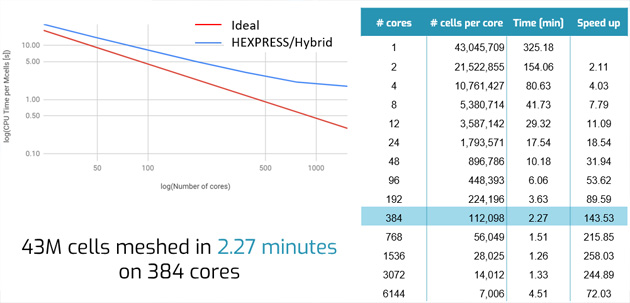

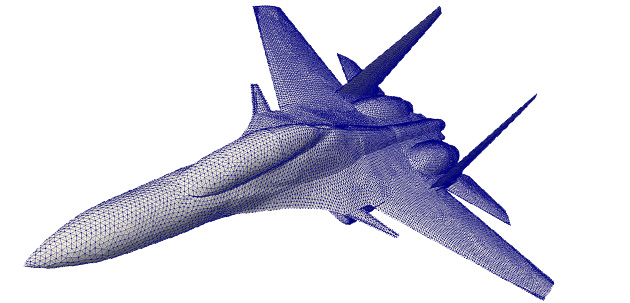

Accurately predicting vehicles' external aerodynamics, heating, ventilation, and air conditioning requires setting up simulation domains that consist of many components in CAD format. The main difficulty in working with so many components is creating the so-called watertight surface needed to perform proper CFD analysis with a finite-volume solver. This requires closing gaps, eliminating surfaces not in contact with the fluid, and solving interference issues before a surface and volume mesh can be generated. These tasks are usually performed manually, using pre-processing software with CAD handling and mesh-generation capabilities, and it takes considerable work and time.

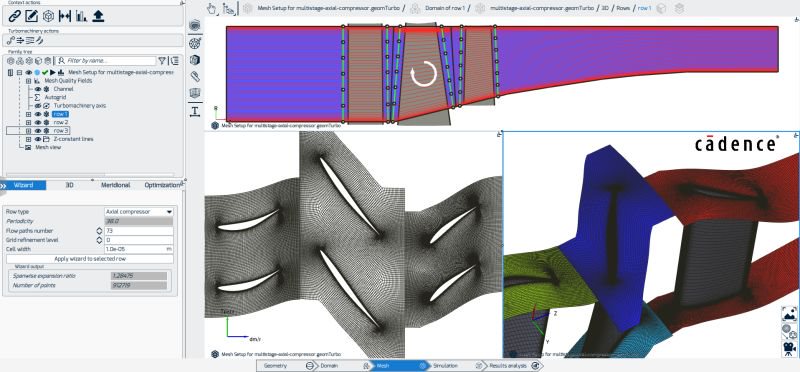

Toyota managed to eliminate this part of the process by setting up a pre-processing workflow within Fidelity Automesh. In this webinar, Toyota explains how.