Webinar

Toyota Drastically Reduces Simulation Time with Automatic CFD Pre-Processing Workflow

Creating a detailed CFD model for automotive applications normally requires a huge amount of manual work. Toyota eliminated this work thanks to an innovative CFD pre-processing workflow and, in this CadenceTECHTALK™, they will show you how.

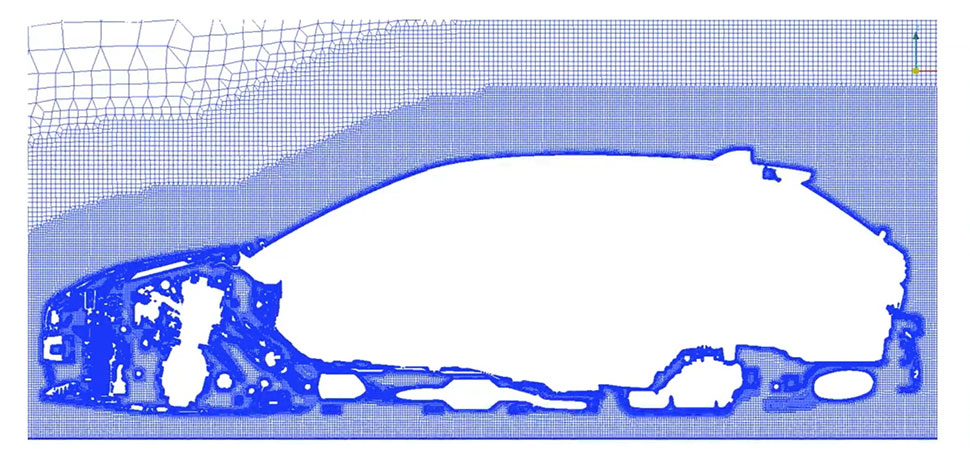

Accurately predicting external aerodynamics, heating, ventilation, and air conditioning of vehicles requires setting up simulation domains that consist of a high number of components in CAD format. The main difficulty in working with so many components is creating the so-called watertight surface that is needed to be able to perform proper CFD analysis with a finite volume solver. This requires:

- closing gaps

- eliminating surfaces that are not in contact with the fluid

- solving interference issues before a surface and volume mesh can be generated.

These tasks are usually performed manually, by using pre-processing software with CAD handling and mesh-generation capabilities, and it takes a considerable amount of work and time.

Toyota managed to eliminate this part of the process by setting up a pre-processing workflow that combines Cadence® Omnis™ AutoSeal technology’s powerful gap closing capabilities with the Omnis Hexpress volume-to-surface meshing approach.