Datasheet

Cadence SIMPLI Mixed-Signal/MEMS Co-design Methodology

For Cadence Virtuoso Users

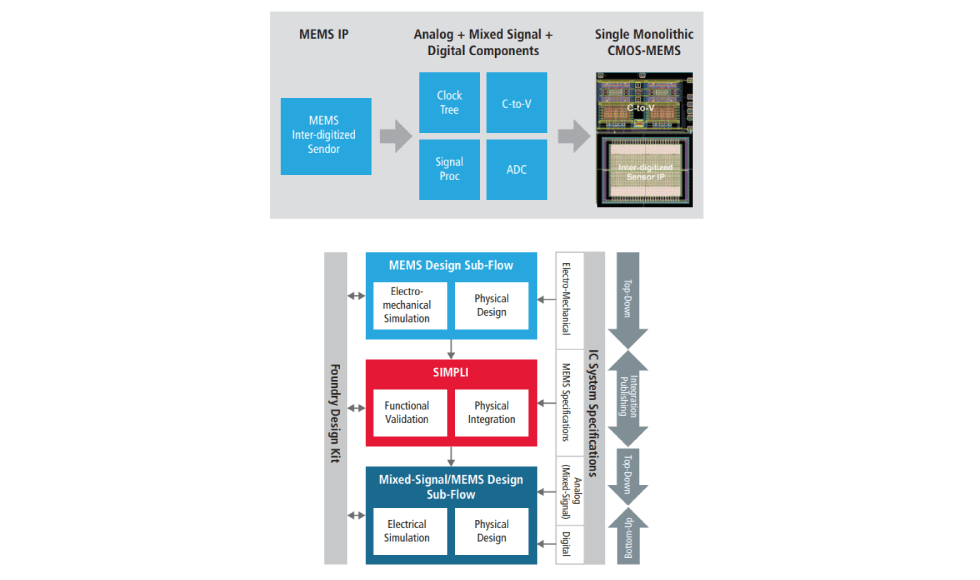

The Cadence SIMPLI Mixed-Signal/MEMS Co-design Methodology handles the special requirements for a MEMS methodology for both system-on-chip (SoC) and system-in-package (SiP) applications. Silicon MEMS Platform Interchange – SIMPLI, which supports Cadence Virtuoso users, ensures efficient handling of concurrent design/optimization of the MEMS and electronics while handling engineering change orders (ECO) between the two domains.

Overview

Overview

With more microelectromechanical systems (MEMS) being widely used for automotive and consumer electronics, the need for a robust MEMS and mixed-signal co-design flow is becoming crucial. This flow should equally enable system-onchip (SoC) and system-in-package (SiP) approaches. A clear-cut interface between a MEMS design sub-flow and the conventional mixed-signal sub-flow is necessary.

Provided as Virtual Integrated Computer-Aided Design (VCAD) Productivity Package, the Cadence SIMPLI Mixed-Signal/MEMS Co-design Methodology handles the special requirements for a MEMS methodology for both SoC and SiP applications.

SIMPLI ensures efficient handling of concurrent design/optimization of the MEMS and electronics while handling engineering change orders (ECO) between the two domains.

A Monolithic Mixedsignal / MEMS Co-design Methodology

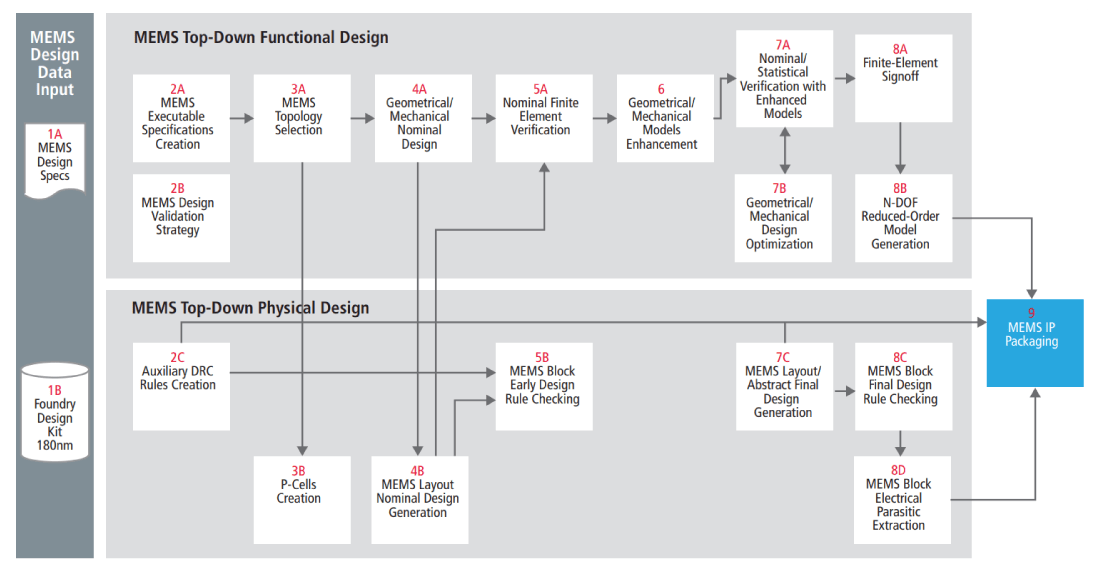

The MEMS sub-flow follows a top-down approach starting with behavioral modeling down to finite-element simulation.

For the MEMS sub-flow, a Cadence-based design sub-flow is readily available, yet the flow is equally portable to many third-party MEMS point tools through the use of SIMPLI.

The proposed MEMS sub-flow is demonstrated by 18 design tasks. An x-axis MEMS accelerometer design has been chosen to demonstrate these design tasks from specifications to publishing.

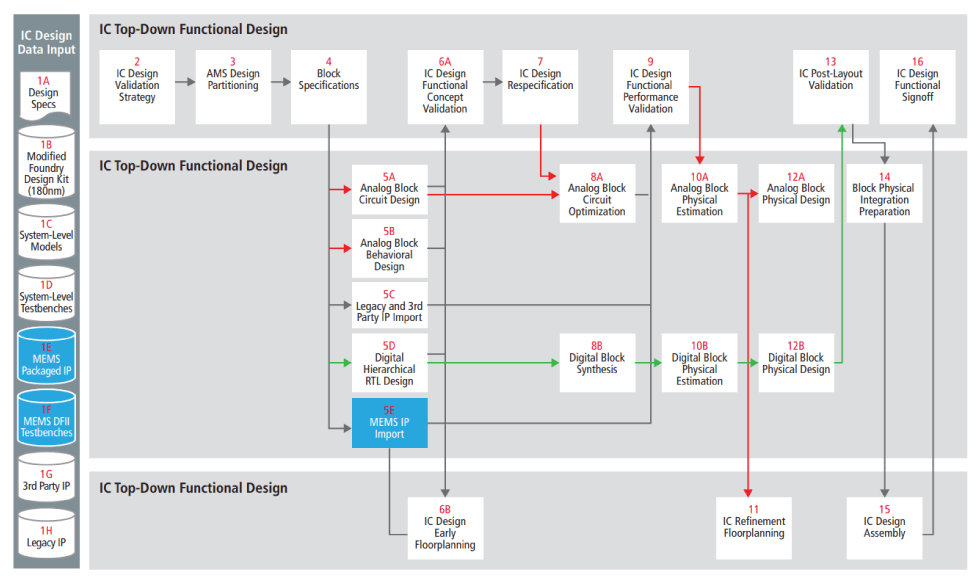

A meet-in-the middle approach is used for the mixed-signal sub-flow, a variant of the Cadence AMS Design Methodology. This will decrease the entry barrier for the integration of the MEMS structure. On the other hand, most of the specific steps that have to be handled by mixedsignal designers due to the presence of the MEMS structure are handled from a single cockpit called SIMPLI. Thus, mixed-signal designers will not need special training on the MEMS sub-flow.

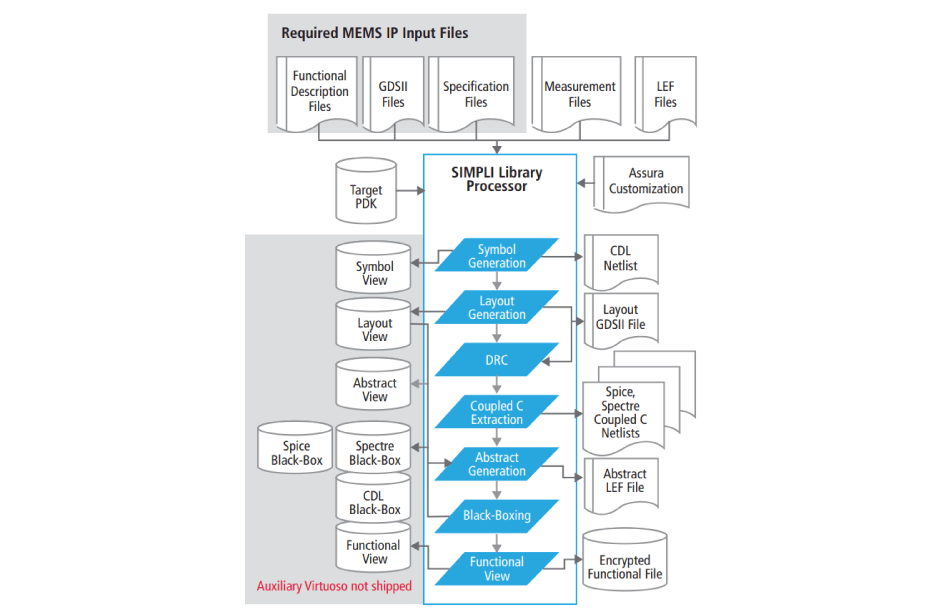

SIMPLI: An IP Publishing and Importing Interface Dedicated to the MEMS Domain

One challenge in the co-design of the MEMS and the mixed-signal portions of the chip is the fact that they might not necessarily share the same flow. Moreover, the information required by the mixed-signal design team might not be readily available from the MEMS point tools.

An extra layer is needed to automate the generation of all the necessary information from the MEMS tools, while still allowing for IP protection.

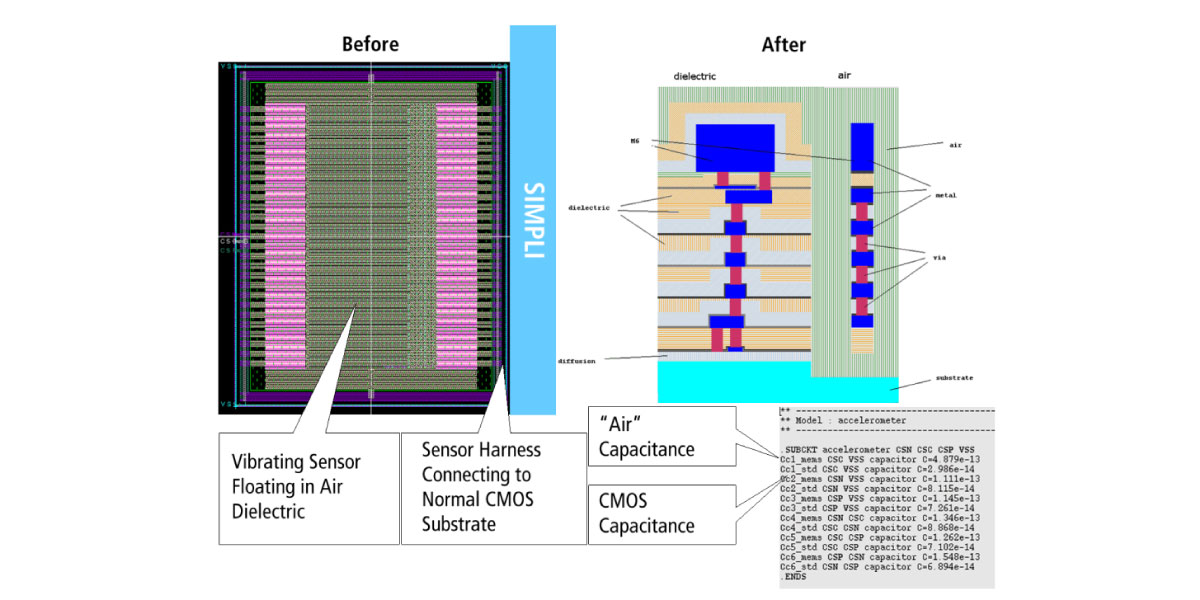

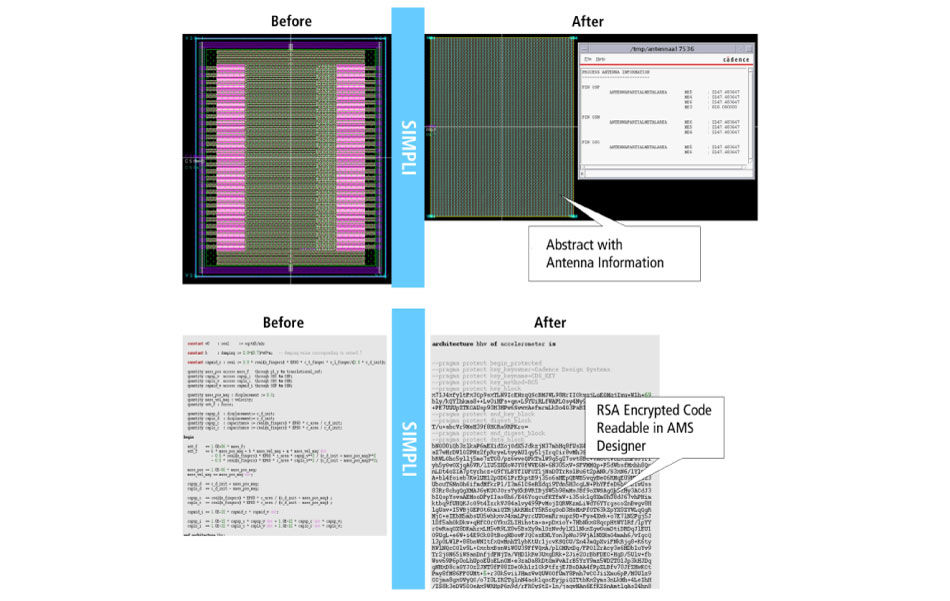

SIMPLI operates on standard inputs and generates views required for mixedsignal design within the Cadence Design Framework.

Moreover, SIMPLI automates the extraction of parasitic coupling capacitances at the interface with the released MEMS structure.

With SIMPLI, you have the flexibility to export your layout as an abstract view and the behavioral or reduced-order models in a 128-bit RSA encrypted format, which will still be useful for simulation by the mixed-signal design group.

SIMPLI Inspect

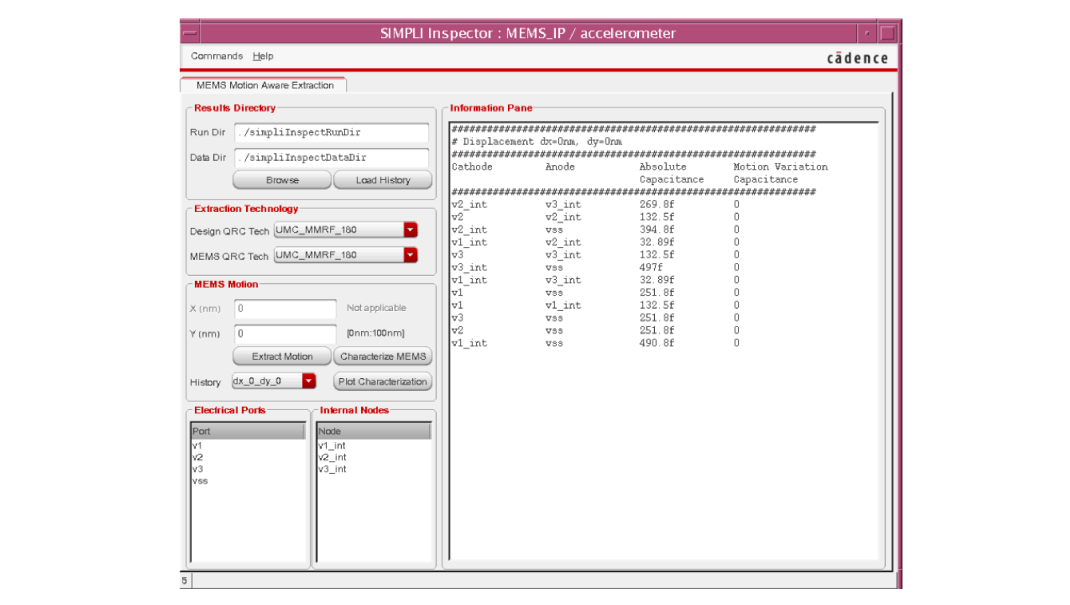

The purpose of SIMPLI Inspect is to help generate the necessary motion-aware parasitic capacitance contribution. SIMPLI Inspect can be used by either the MEMS or IC design teams, provided that the layout was originally created by SIMPLI.

MEMS Characterize lets you specify the number of points for extraction. The range of values are defined as part of the SIMPLI spec file and are saved together as part of the layout database.

You can identify the number of displacements either by the Linear Step Size or Number of Points. SIMPLI Inspect starts to move the floating part (saved as sub-instance) with respect to the fixed frame, and each time carry out the extraction using Cadence QRC Extraction.

MEMS Methodology Flows

The MEMS methodology is represented as three major flows. Each flow contains several executable scenarios.

VCAD Productivity Packages

VCAD Productivity Packages are a set of pre-packaged generic core solutions that increase design system productivity. Productivity Packages are available within services contracts, which include the package integration and maintenance of the customized solution. Cadence VCAD services targets the development, implementation, and ongoing improvement and maintenance of productive design systems to ensure short time to market and silicon success.

SIMPLI is available through Cadence VCAD Services. For more information, please contact:

Louis Thiam

Tel.: +49 89 4563 1957

E-mail: thiam@cadence.com

Ahmed Hussein Osman

Tel.: +49 89 4563 1737

E-mail: ahmedo@cadence.com

Cadence Design Systems GmbH

Mozartstrasse 2 85622 Feldkirchen

Germany